HGM100 ultrafine powder grinding mill- Xinjiang, China

Table of Contents

About Case

When drilling some oil and gas wells, the specific gravity of drilling mud and clay commonly used is about 25, and the specific gravity of water is 1. Therefore, the specific gravity of the mud is low, and sometimes the weight of the mud cannot balance with the underground oil and gas pressure, which can easily cause a blowout accident. When the underground pressure is high, the mud weight needs to be increased.

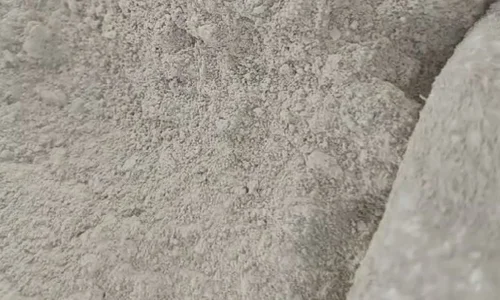

Adding barite powder to mud is an effective measure to increase the specific gravity of mud. The barite used for drilling mud generally has a fineness of more than 325 mesh. If the barite is not fine enough, precipitation will easily occur. Barite powder for drilling mud requires a specific gravity greater than 4.2, a BaSO4 content of not less than 95%, and soluble salts.

Barite fine powder used for drilling mud needs to be above 325 mesh. In order to ensure the stable supply and fineness of ultra-fine powder, local customers contacted our sales manager to communicate production needs. Local customers contact our sales manager to communicate their production needs through our official website, the cutting-edge level of Clirik equipment has been proven by its strength in Xinjiang.

Production Line Configuration

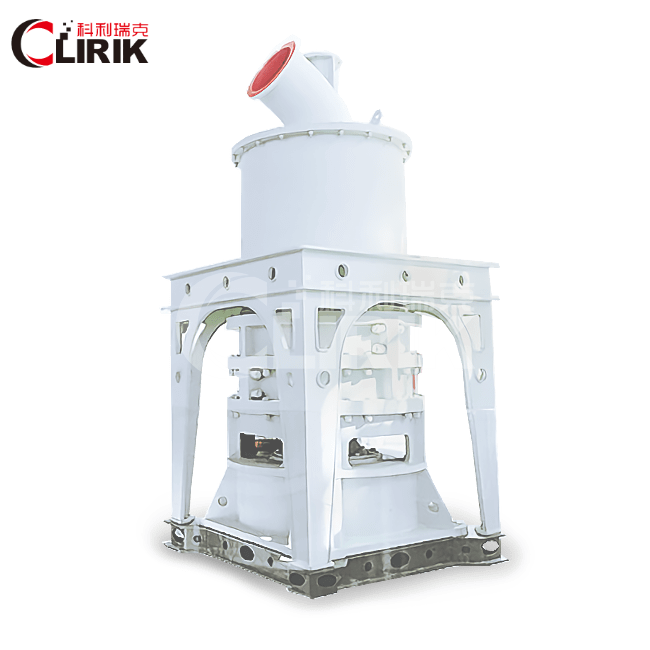

According to the customer’s demand for production and fineness, in the HGM series ultra-fine mill production line with an ultra-wide adjustment range of 200-2500 mesh, Clirik selects HGM100 ultrafine powder grinding mill equipment to prepare high-specification barite fine powder of 800 mesh, and match the production capacity demand with a large hourly output of 4 tons.

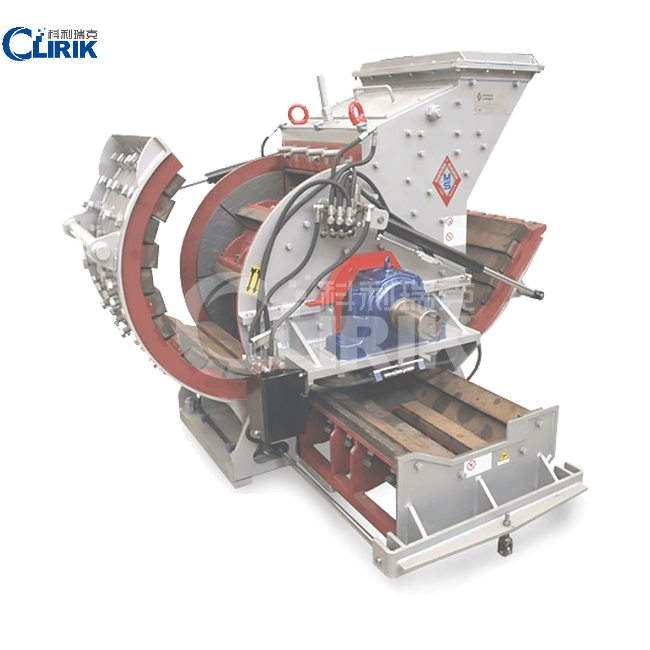

The production line consists of crushing, transportation, powder grinding, powder collection and other parts.

1. It integrates a series of equipment components with excellent quality and excellent performance such as main machine, powder separator and powder collector.

2. It embodies Clirik accumulated experience in the fine milling industry for more than ten years and examples of equipment production.

3. It is a high-quality HGM100 ultrafine powder grinding mill production line independently developed with the support of various patented technologies, continuous innovation, and closely following international technology and process concepts.

Project Advantage

● Finished product quality is stable

The special grinding structure of the equipment forms a stable material layer and the material stays in the mill for a short time, reducing repeated grinding; ensuring that the particle size and chemical composition of the finished product bring more stable product quality.

● Energy efficient

Reducer equipped with circulating oil lubrication system and circulating water cooling system;

The production line has all-weather operation capabilities, and the power consumption per ton can be saved by 30% compared with similar mills.

● High precision

The equipment optimizes the distance between the rotor blades of the classifier to simultaneously improve classification accuracy and efficiency;

Adopting a horizontal graded turbine device, the speed is higher and the top cutting is more accurate.

● Double insurance to avoid dust spillage

Unique sound-absorbing room design reduces noise pollution;

The entire negative pressure working system makes the entire equipment sealed;

Using gas transportation technology, the finished products go directly into the large finished product warehouse to avoid dust spillage.

● Considerable benefits

After several months of operation, the equipment has been running smoothly and efficiently;

The discharged particle size distribution is uniform and the specific surface area is large;

The actual production capacity exceeded the set target and created considerable production income.

Customer On-site Display

Application Of 800 Mesh Barite Powder

Barite powder, which is typically ground to various mesh sizes, finds application in a variety of industries due to its unique properties. The 800 mesh barite powder, being finely ground, can have several applications, including:

Oil and Gas Industry: Barite is primarily used as a weighting agent in drilling muds in the oil and gas industry. The finely ground 800 mesh barite powder can be utilized to increase the density of drilling fluids, which helps to control pressure and prevent blowouts during drilling operations.

Paints and Coatings: Barite is used as a filler in paints and coatings to enhance properties such as durability, opacity, and resistance to corrosion. The fine particle size of 800 mesh barite powder allows for smoother finishes and improved performance in coatings.

Plastics and Rubber: Barite powder is added to plastics and rubber products to improve their mechanical properties, such as hardness, stiffness, and abrasion resistance. The 800 mesh barite powder can be uniformly dispersed in polymer matrices to achieve desired properties in the final products.

Construction Materials: In the construction industry, barite is used as an aggregate in concrete to increase the density and improve radiation shielding properties. The finely ground 800 mesh barite powder can be incorporated into concrete formulations to produce high-density concrete for applications in nuclear facilities or medical facilities.

More Barite Grinding Equipment Recommended

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40