Barite Powder High Pressure Suspension Grinding Mill In Nigerian

Table of Contents

About this case

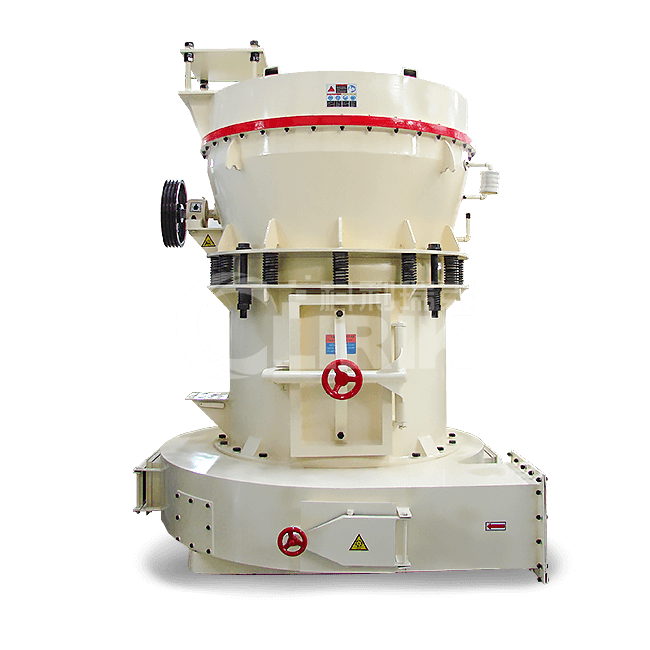

Nigerian barite powder enterprises have recently introduced a set of high-efficiency barite mill production lines to improve the production efficiency and product quality of barite powder.

This production line is provided by Clirik, a leading mill manufacturer in China. We provide customers with high-performance YGM series barite powder high pressure suspension grinding mill, vibrating feeders, electric control cabinets and other equipment.

The production line adopts the most advanced technology and workmanship, which is characterized by high efficiency, stability and safety, and can meet the production needs and quality requirements of customers. After a long period of operation and practical testing, the production line has a very good operating effect, and the production efficiency and product quality have been significantly improved, which has been highly praised by customers.

According to the customer, the use of this production line not only improves production efficiency and product quality, but also reduces operating costs, bringing tangible economic and environmental benefits. At the same time, they are also very satisfied with the thoughtful after-sales service provided by the manufacturer.

The successful case of this Nigerian mining enterprise is not only a reflection of the technical strength and brand influence of domestic mill manufacturers, but also a concrete achievement of the economic and trade cooperation between China and Nigeria. The two sides have broad cooperation space and prospects in terms of resource complementarity and technical cooperation. In the future, the two sides will continue to deepen cooperation and jointly promote the development of China-Nigeria economic and trade cooperation to achieve mutual benefit and win-win situation.

About of Barite Powder High Pressure Suspension Grinding Mill

Barite powder high pressure suspension grinding mill working principle

The working principle of Barite powder high pressure suspension grinding mill is to crush the material, grind the material under the action of high-pressure grinding roller, and sort out the fine powder through the analyzer and cyclone collector.

1. The large-sized barite material is crushed by the jaw crusher to the required particle size, and then sent to the storage hopper by the elevator. The vibrating feeder feeds the material uniformly and continuously into the main machine for grinding.

2. The material is ground by the high-pressure grinding roller. Under the action of the high-pressure spring and centrifugal force, the grinding roller rolls tightly against the grinding ring, and the material is ground into powder between the grinding roller and the grinding ring.

3. The fine powder is sorted out by the analyzer, and the coarse powder will fall back to the grinding chamber for regrinding. The airflow enters the cyclone collector, and the separated fine powder is discharged through the discharge valve. The purified airflow is discharged through the pipeline, and the whole process is completed.

Barite powder high pressure suspension grinding mill characteristic

Barite powder high pressure suspension grinding mill is a new type of mill designed by Clirik Machinery, which is characterized by its high pressure, low energy consumption, energy saving, high efficiency, and high fineness.

The main characteristics of the Barite powder high pressure suspension grinding mill are as follows:

1. High pressure

The grinding roller of the barite powder high pressure suspension grinding mill is tightly pressed on the grinding ring by the high pressure spring. The pressure of the grinding roller is increased by 800-1200kg, which makes the grinding process more efficient and the fineness of the finished product finer.

2. Low energy consumption

The energy consumption of the mill is reduced by 30-40% compared with the traditional mill, which greatly reduces the production cost.

3. Energy-saving

The grinding mill is equipped with a pulse dust collector and a muffler, which can reduce dust pollution and noise, and achieve the purpose of energy-saving and environmental protection.

4. High efficiency

The grinding mill is equipped with a high-efficiency separator, which can separate the fine powder in the finished product in time, and avoid over-grinding and reduce energy consumption.

5. High fineness

The finished product can reach 0.038-0.18mm, and the passing rate of the finished product can reach 97%, which meets the requirements of various industries for particle size.

Barite powder high pressure suspension grinding mill has the characteristics of high pressure, low energy consumption, energy saving, high efficiency, and high fineness, which can meet the production needs of various industries and provide high-quality powder products for customers.

About of Clirik

SHANGHAI CLIRIK MACHINERY CO., LTD is specialized in the research, development, and production of crushing equipment, grinding equipment, screening equipment and mineral processing equipment.

Our Workshop

Our company adopts 5S to manage the production workshop. When entering the workshop, it is necessary to wear a safety helmet, keep the production table clean, and put the items unrelated to production in the designated position.

Our Technology

Our pursuit of production output at the same time pays more attention to the quality of products. We produce every product through our strict measurement, only meet the production requirements of the product will be sent to your hands.

Our Delivery

We will carefully check the purchased equipment, label the product name for your acceptance, and use packaging bags for packaging, to ensure that after you receive the equipment, the assembly and production will not be affected because of the lack of parts.

Our Installation

We will provide professional engineers to your site for installation, as well as technical training for your operators.If there are other after-sales problems in the later period, we will also have professional personnel to provide after-sales service for you.

For more information please click here to leave us a message and our sales manager will contact you later.

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40