Barite Powder High Pressure Suspension Grinding Mill

Table of Contents

- 1 Product Overview Of Barite Powder High Pressure Suspension Grinding Mill

- 2 Product Application Of Barite Powder High Pressure Suspension Grinding Mill

- 3 Product Features Of Barite Powder High Pressure Suspension Grinding Mill

- 4 Working Principle Of Barite Powder High Pressure Suspension Grinding Mill

- 5 Product Parameter Of Barite Powder High Pressure Suspension Grinding Mill

- 6 Introduction Manufacturer of Barite Powder High Pressure Suspension Grinding Mill

- 7 FAQ

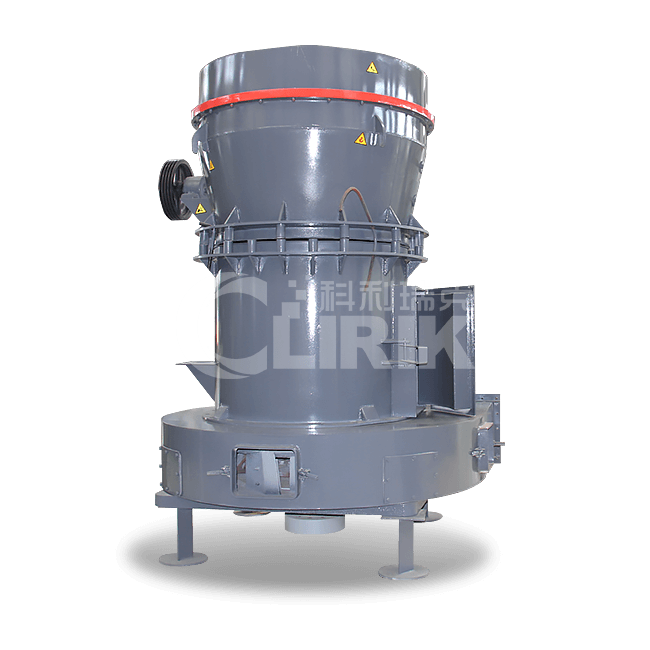

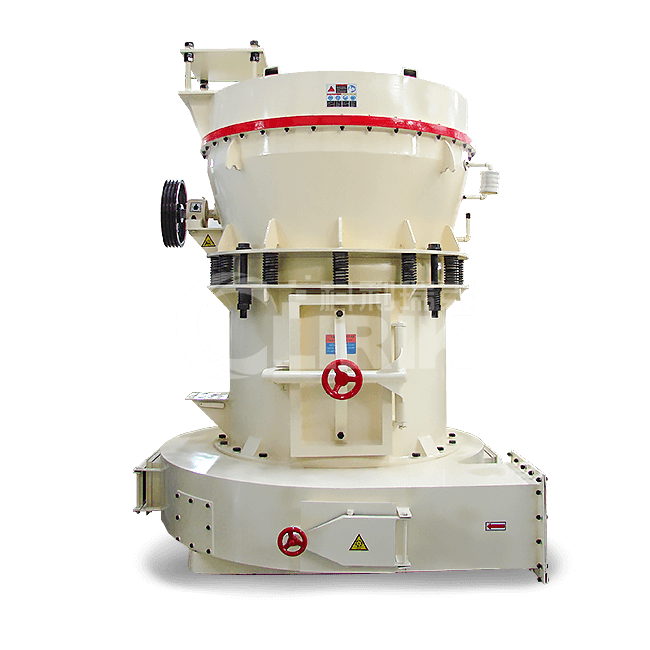

Product Overview Of Barite Powder High Pressure Suspension Grinding Mill

Barite powder high pressure suspension grinding mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. The finished powder size can be adjusted between 30 and 425 mesh (0.613mm-0.044mm). We have 5 models: YGM7815, YGM9517, YGM1280, YGM1300, YGM1620, YGM1720 roller Raymond mill for your choice.

Barite Powder High Pressure Suspension Grinding Mill

Model : YGM series

Brand : Clirik

Fineness Size : 50-325 mesh

Capacity : 1-25 t/h

Use Range :Barite ,Calcium Carbonate,Dolomite,Gypsum,Carbon Black,Glass,Gypsum,Kaolin,Marble …

Application : Mining, Chemiscal, Transport and many other different areas.

Product Application Of Barite Powder High Pressure Suspension Grinding Mill

Barite powder high pressure suspension grinding mill can be used to process more than 280 non-flammable and explosive materials with a Mohs hardness of less than 9.3 and a humidity of less than 6%, such as barite, calcite, and potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation, etc.

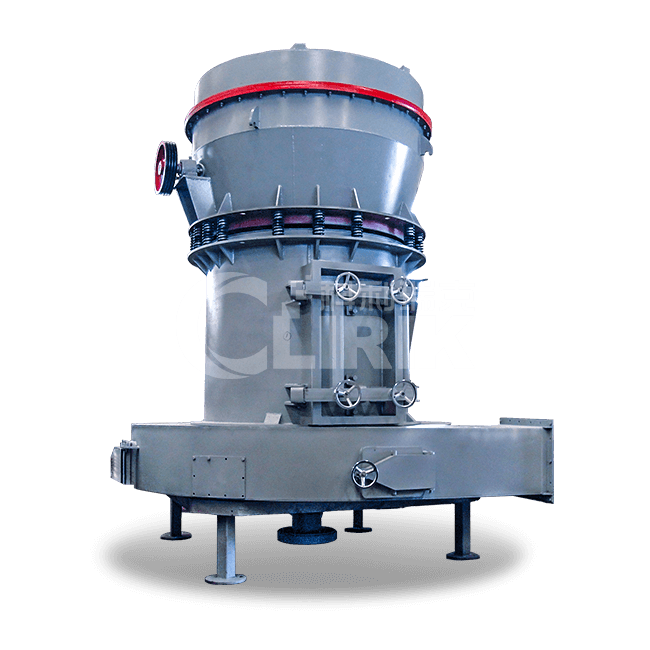

Product Features Of Barite Powder High Pressure Suspension Grinding Mill

1.Bevel gear integral transmission.

The traditional grinding mill needs a decelerator and ratcheting to drive the main shaft that increases the centering difficulty and is easy to bring noise as well as reduce the efficiency. Barite Powder High Pressure Suspension Grinding Mill adopts bevel gear integral transmission that compact the whole structure and simplifies the installation as well as improves the efficiency.

2.Inner light-oil lubrication system.

The traditional grinder machine lubrication adopts grease lubrication which increases the resistance of lubrication, creates high inherent temperature and shortens the service life of bearing. Barite Powder High Pressure Suspension Grinding Machine adopts light-oil lubrication to achieve the lubrication of bearing without oil pump and lubrication station.

3.Arc whirl tube.

The traditional mills adopt board-type whirl tube that increases the resistance, reduces the performance, and stops the air flow and so on. YGM Series Barite Powder grinder machine adopt arc whirl tube reduce the resistance and avoid the air-stop and so on.

4.Wear resistant alloy material.

The edge of Barite Powder High Pressure Suspension Grinding Mill adopts wearable alloy materials which improve the service life. The Changeable edge is easy to change that saves time and cost. The traditional flat shovel makes the materials accumulate at one level that reduces the ring and roller service life. The curved surface shovel makes a vertical material liner which increases the working face and capacity.

5.Insolating type cyclone collector.

Adopt insolating structure between the inner core and mixed air flow that improve the classifying efficiency and precision.

6.Non-resistance inlet shell.

Traditional observation door of shell protrude that makes the inner surface is not so smooth, which brings eddy effect and increases the consumption. YGM Series Barite Powder Raymond Grinding Mill adopts the same curved surface which avoids the eddy effect.

7.Fine appearance.

Barite Powder High Pressure Suspension Grinding Mill not only adopts many advanced structures but also optimizes the appearance.

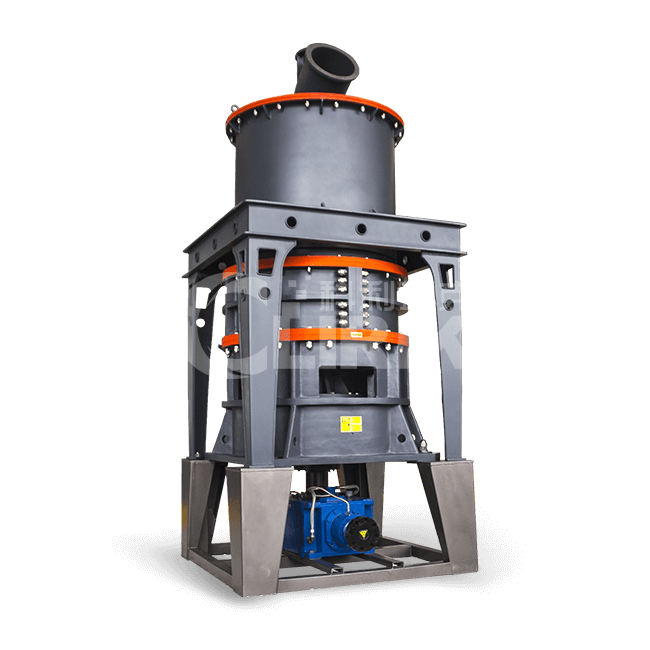

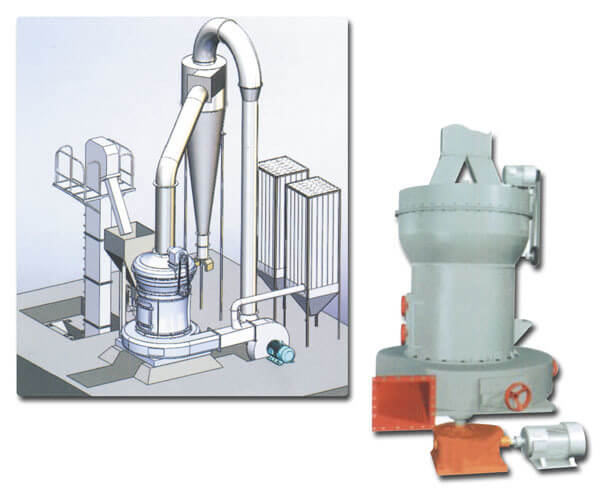

Working Principle Of Barite Powder High Pressure Suspension Grinding Mill

The standard configuration of barite powder high pressure suspension grinding mill consists of main unit, reducer, powder classifier, cyclone powder collector, dust cleaner, blower, control cabinet motor and pipes. The optional accessories include a crusher, bucket elevator, vibrating feeder.

The raw material is crushed to less than 20 mm by the jaw crusher and then lifted to the storage hopper by the elevator. Then through the feeder, the raw materials are uniformly, quantitatively, and continuously sent to the main machine for grinding.

The ground powder is blown away by the airflow and separated by a classifier. The powder conforming to the fineness enters the cyclone collector through the pipe with the airflow and is separated and collected. Finally, the powder in the tube is discharged into finished powder.

The large cyclone collector is arranged at the upper end of the suction fan of the return duct, and the airflow of the whole system is a closed-loop, which flows and circulates under the state of positive and negative pressure.

Product Parameter Of Barite Powder High Pressure Suspension Grinding Mill

| Model | Roller | Ring | Feeding Size(mm) |

Finished Size(mm) |

Mill System Power(KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1.0-3.0 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12.0 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16.0 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8.0-20.0 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28.0 | 11550*9500*1050 |

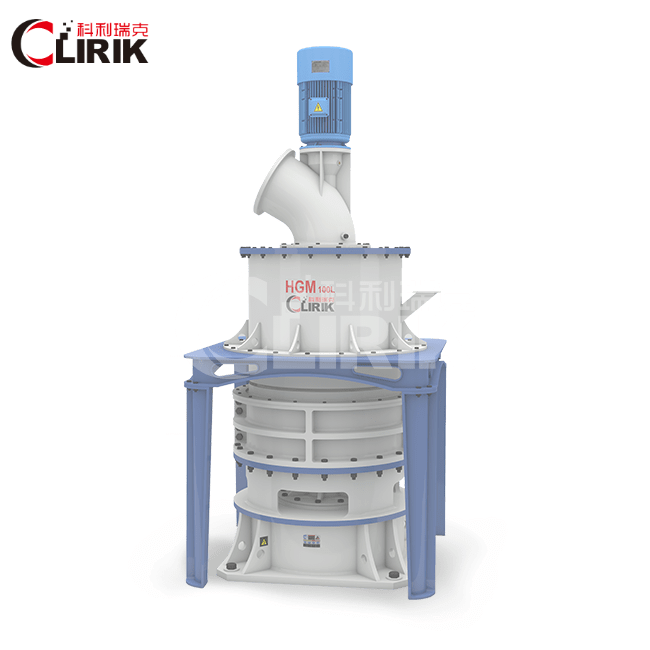

Introduction Manufacturer of Barite Powder High Pressure Suspension Grinding Mill

Our company

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai China as a professional enterprise, which specializes in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production lines, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

From the design, production, installation and debugging, we provide you with the entire tracking service. We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

Our transportation

We will carefully check each product purchased by the customer and make good packaging to ensure that the customer can assemble and use after receiving it.

Our Certificate

Clirik barite powder high pressure suspension mill has obtained a number of product patents and certification.

Our Services

Pre-sale service:

1. Clirik provides a variety of mining equipment for you to choose from.

2. Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3. Clirik customizes the logo and color of the grinding equipment according to your company image.

4. Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and uses videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for grinding equipment.

FAQ

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40