Table of Contents

Product Overview

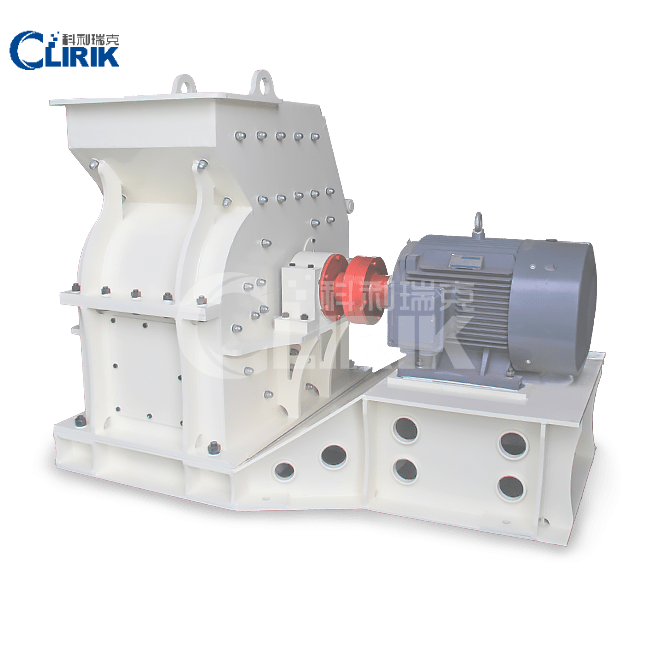

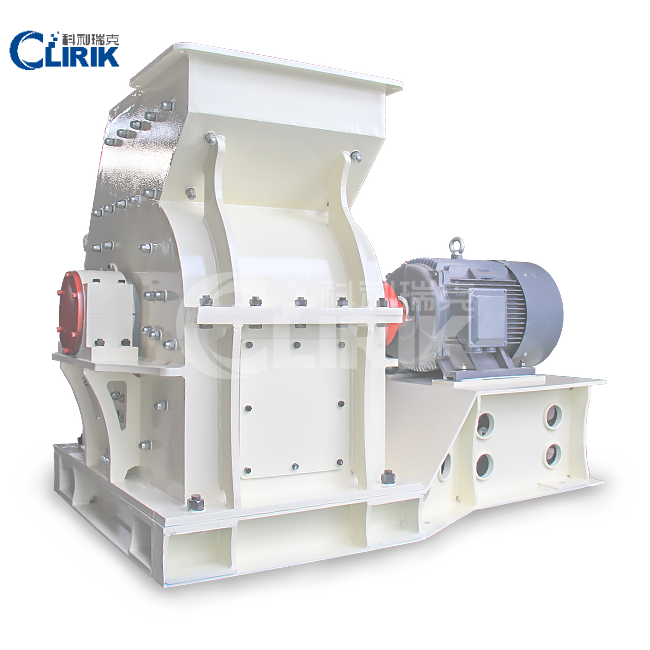

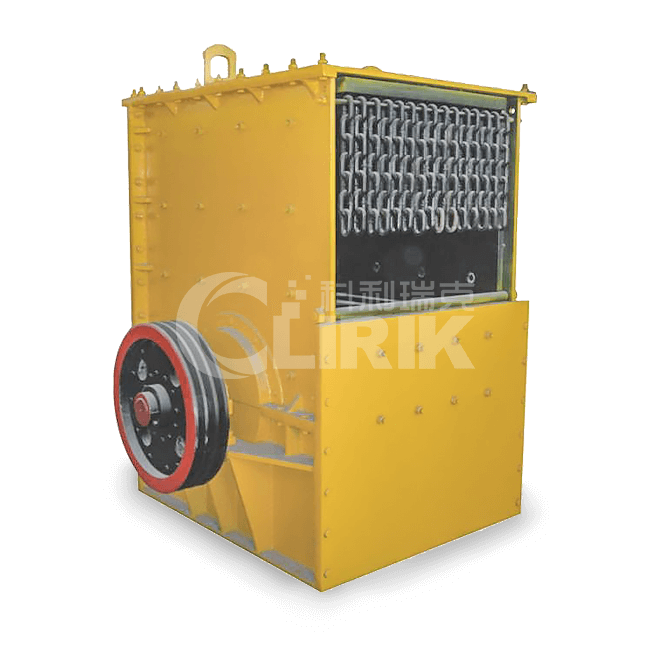

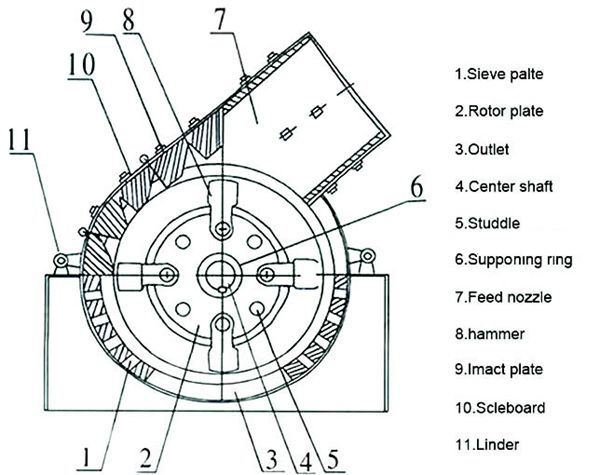

PC Series Hammer Crusher

Output Size: 5-20 mm

Feed size.: <350 mm

Capacity: 5-30 t/h

Use Range : Calcite、Calcium Carbonate、Dolomite、Gypsum、Carbon Black、Gypsum、Kaolin、 Marble …

Application : Mining、Chemiscal、 Pigment、 Plastic、Transport and many other different areas.

Product Parameter

| Model | PC400x300 | PC600x400 | PC800x600 |

| Rotor Diameter (mm) | 400 | 600 | 800 |

| Rotor Length (mm) | 300 | 400 | 600 |

| Rotor Speed(r/min) | 1100 | 1000 | 900 |

| Max. Feeding Size(mm) | <100 | <220 | <350 |

| Ouput Size(mm) | 5-10 | 5-15 | 5-20 |

| Capacity(t/h) | 5-13 | 10-20 | 18-30 |

| Motor Power(kw) | 11 | 18.5 | 45 |

| Moisture of feeding material | <3% | <3% | <3% |

| Number of Hammer(piece) | 16 | 20 | 28 |

| Weight(t) | 0.8 | 1.8 | 2.8 |

| Overall Dimension (L*W*H/mm) | 900*670*860 | 1200*1050*1200 | 2360*1490*1415 |

| Note: This specification is just referencing, any changes are subject to the products. | |||

Product Application

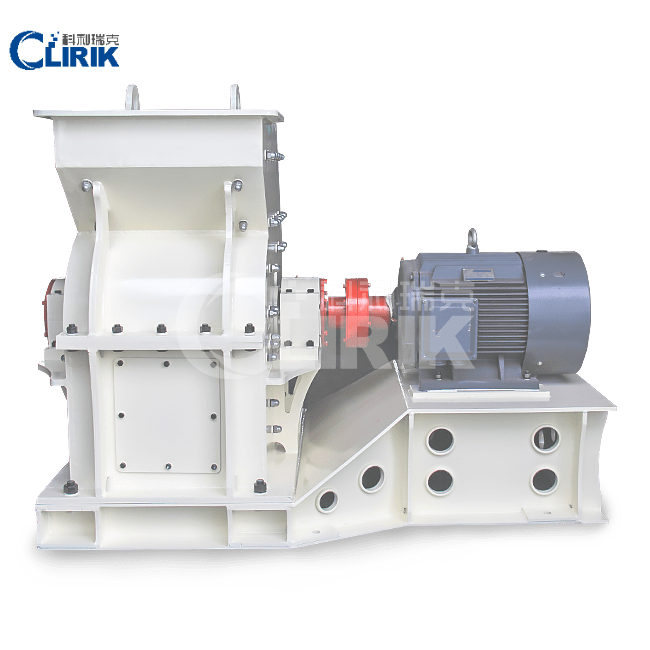

PC Series Hammer crusher is equipment using high-speed rotary hammers to crush materials, mainly applied to the industries of metallurgy, mining, chemistry, cement, construction, refractory materials and ceramics. It can crush hard and soft ores into medium or small size, such as barite, limestone, gypsum, terrazzo, coal, slag, and up to 100 different kinds.

Working Principle

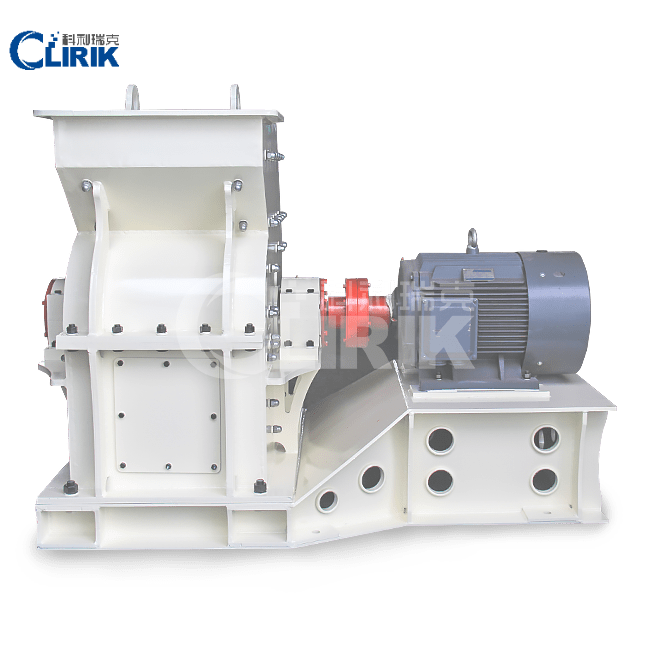

PC Series Hammer crusher mainly consists of frame, rotor, support iron and grate bars. The frame is divided into two parts: upper part and lower part which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of the turn plate, pin shafts, and hammers which are grouped regularly in the main shaft. The motor drives the rotors to rotate quickly in the crushing cavity, and hammers spread outward as a result of centrifugal force from the rotation of the rotors.

Large materials entering the crusher through the feed inlet are stricken, impacted, cut and ground by the high-speed hammers to small size. Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirement.

Product Advantage

The working hammer is cast with a new technology, which is wear-resistant and impact-resistant.

The required granularity can be adjusted according to customer requirements.

The structure of the machine body is sealed, which solves the problems of dust pollution and ash leakage of the machine body in the crushing workshop.

The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

Operation& Maintenance

How to operate and check the PC series hammer crusher?

(1) Before starting and stopping, get in touch with the upper and lower procedures related to the machine, and perform correct operations in the order of starting and stopping.

(2) To start the truck empty, pay attention to the material in the crushing cavity before stopping the machine.

(3) Regularly check all the anchor bolts and liner bolts of the equipment for any looseness. If they are loose, they should be tightened in time.

(4) Frequently check the use of easily wearable parts such as hammerheads and liners. If any problems are found, they should be dealt with in time.

(5) Always check the lubrication situation and keep the lubrication system in good condition. The temperature of the rotor bearing should be kept below 60 °C, and the maximum temperature should not exceed 70 °C. If over-temperature is found, the cause should be found out and measures should be taken to eliminate it in time.

(6) Keep the feed evenly, and pay attention not to feed metal debris.

(7) Pay attention to check whether the discharge particle size meets the quality requirements. If not, replace the grate bar or adjust the height of the grate bar bracket.

Safety precautions :

(1) If the equipment has an emergency failure during operation, it can be stopped first. Do not drive forcibly until the fault is eliminated.

(2) If electrical equipment fails, electrical personnel should be responsible for handling.

(3) When you need to enter the internal inspection of the machine, you must first pull out the power switch and hang up a sign for maintenance. Before the inspection, the materials in the upper part of the machine should be cleaned to prevent falling and hurting people. Before the test is completed, the upper cover must be covered and the bolts must be tightened.

(4) All safety devices must be complete and firm. When the contact signal and communication equipment fail, the crusher cannot be started.

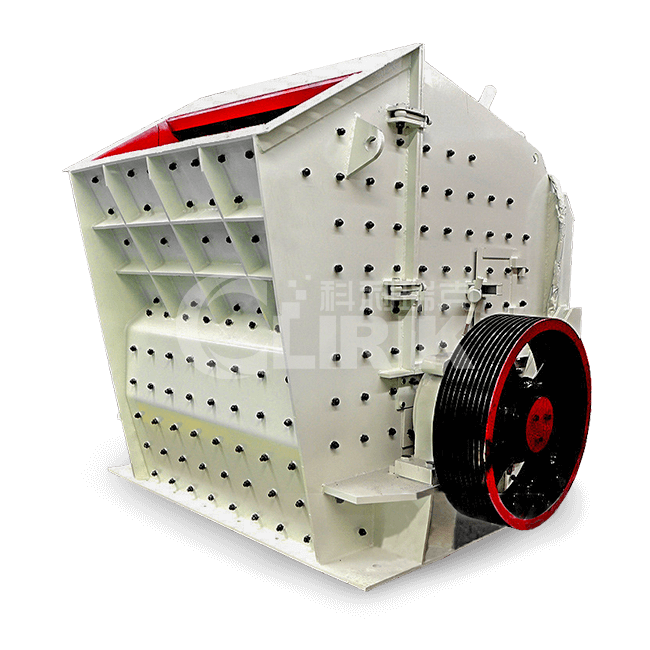

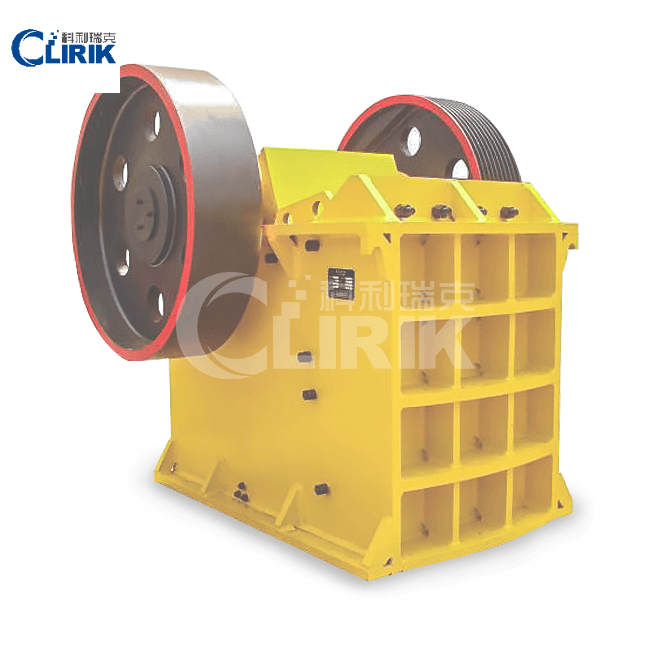

Other Products Offered

Company Profile

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent,standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40