Table of Contents

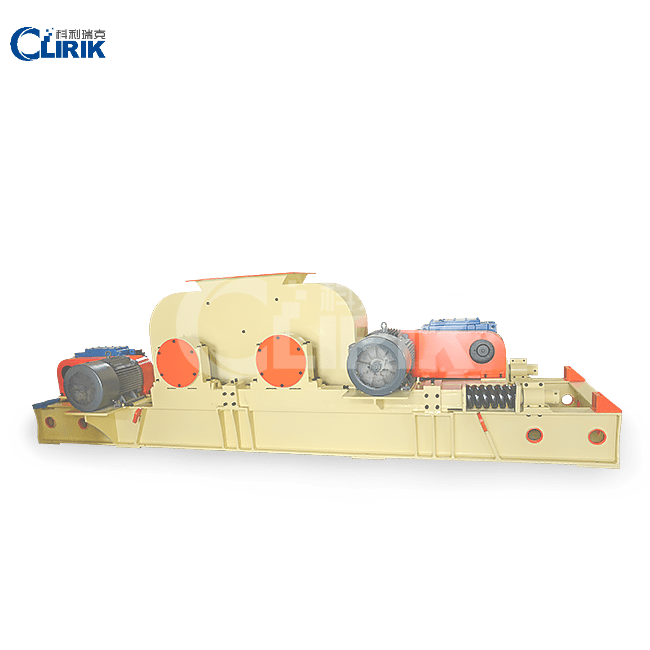

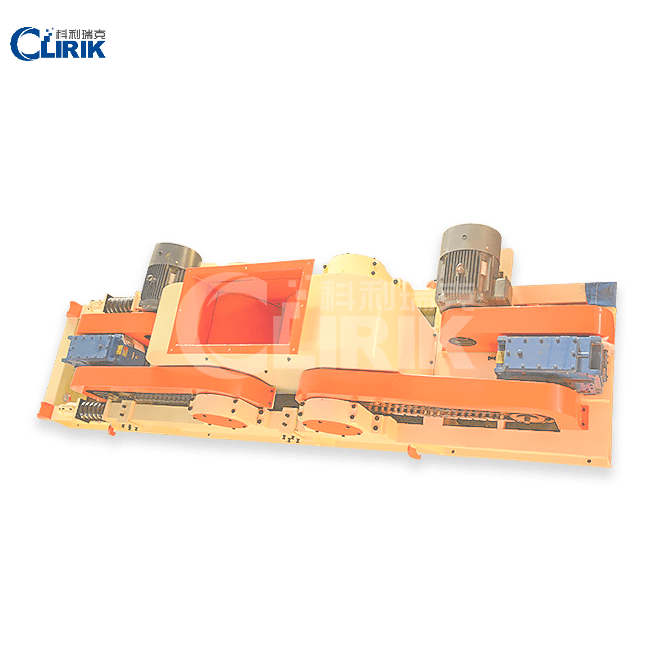

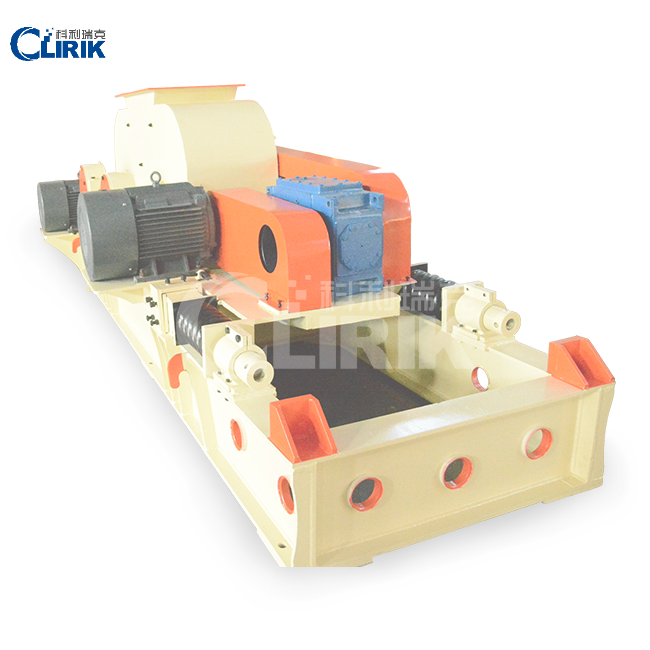

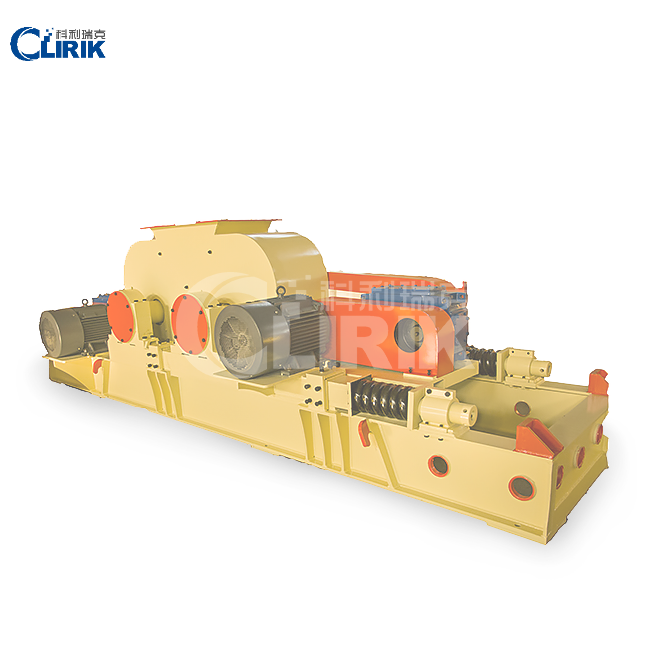

Producte Overview Of Roll Crusher

Roll crusher is a new product designed and developed by itself with reference to the structural principle of the American Gunlake crusher. The roller crusher has a large crushing capacity.

The motor and the reducer are linked by a distance-limited hydraulic coupling to prevent power overload and sensor overload protection, which is safe and reliable. The spacing of the gear rollers is hydraulically adjusted, and the gear roller bearings are lubricated centrally. Optimized design of tooth shape, selective crushing of tensile and shear forces, high efficiency and low consumption, and regular granulation.

Roll Crusher

Processing ability: 2-140 t/h

Fineness: 5-30 mm

Max feeding size: <150 mm

Range of application: Barite,Pebble,Granite, Basalt,Iron ore,Limestone,Quartz,Coal, Coke,Clay,Bentonite,Diabase…

Roll crusher has replaced the existing 2PGC roller crusher in China. Suitable for coal, metallurgy, mining, chemical, building materials and other industries, more suitable for large coal mines or coal preparation plant on the crushing of raw coal.

Product Parameter Of Roll Crusher

| Model | Capacity (t/h) | Motor Model | Power (kw) | Overall Dimensions | Weight (kg) |

|---|---|---|---|---|---|

| GF4PG-90 | 70~100 | Y2-250M-6 | 37×2=74 | 2100×2450×2000 | 16100 |

| PCL-750 | 45 | 45-90 | 1500/2500 | 25-55 | 2780*Φ1800*2700 |

| GF4PG-120 | 100~130 | Y2-280S-6 | 45×2=90 | 2100×2750×2000 | 18500 |

| GF4PG-150 | 140~160 | Y2-280M-6 | 55×2=110 | 2100×3000×2000 | 21000 |

| GF4PG-180 | 160~190 | Y2-315S-6 | 75×2=150 | 2500×3000×2400 | 25000 |

| GF4PG-200 | 180~220 | Y2-315S-6 | 75×2=150 | 2500×3100×2400 | 26500 |

| GF4PG-250 | 220~260 | Y2-315M-6 | 90×2=190 | 2500×3330×2400 | 28100 |

| GF4PG-300 | 260~310 | Y2-315L1-6 | 110×2=220 | 2500×3730×2400 | 31200 |

| GF4PG-350 | 300~360 | Y2-315S-6 | 110×2=220 | 2500×3860×2400 | 26500 |

| GF4PG-400 | 350~410 | Y2-315L2-6 | 132×2=264 | 2500×4160×2400 | 36500 |

| GF4PG-450 | 420~460 | Y2–355S-6 | 160×2=320 | 2500×4360×2400 | 40700 |

Working Principle Of Roll Crusher

Roll crusher is mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices.

Roll crushers are classified according to their specifications. The adjustment of the discharge granularity is that a wedge or gasket adjustment device is installed between the two rollers. The top of the wedge device is equipped with an adjustment bolt.

When the adjustment bolt pulls the wedge up, the wedge pushes the movable roller away from the fixed wheel. , that is, the gap between the two rollers becomes larger, and the discharge particle size becomes larger. When the wedge goes down, the gap between the two rollers of the movable roller becomes smaller under the action of the compression spring, and the discharge particle size becomes smaller.

The gasket device adjusts the size of the discharge particle by increasing or decreasing the number or thickness of the gasket. When the gasket is added, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap between the two rollers becomes smaller, and the discharge particle size becomes smaller.

Product Advantage Of Roll Crusher

1. Roll crusher is suitable for a wide range of materials with compressive strength less than 250Mpa can be used for grinding, such as: barite,iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal silicon, barite, basalt , granite, steel slag, cement clinker, construction waste (concrete), shale, quicklime, coal, coke, clay, bentonite, chemical raw materials, etc.

2. Roll crusher has simple structure, small occupied space and convenient operation and maintenance. The interior is equipped with a dust-proof plate, which has good sealing performance and avoids the splashing of small materials after crushing, with less dust, and the working environment is greatly improved. The abrasive roll body is re-optimized design, and the equipment does not need to be replaced for life.

3. Roll crusher can save investment. With compact structure, light weight and small volume, compared with the grinding series with the same production capacity.

4.Roll crusher simple structure, small footprint, convenient operation and maintenance.

5.Roll crusher the interior is equipped with a dust-proof plate, which has good sealing performance and avoids the splashing of small materials after crushing, with less dust and low working noise.

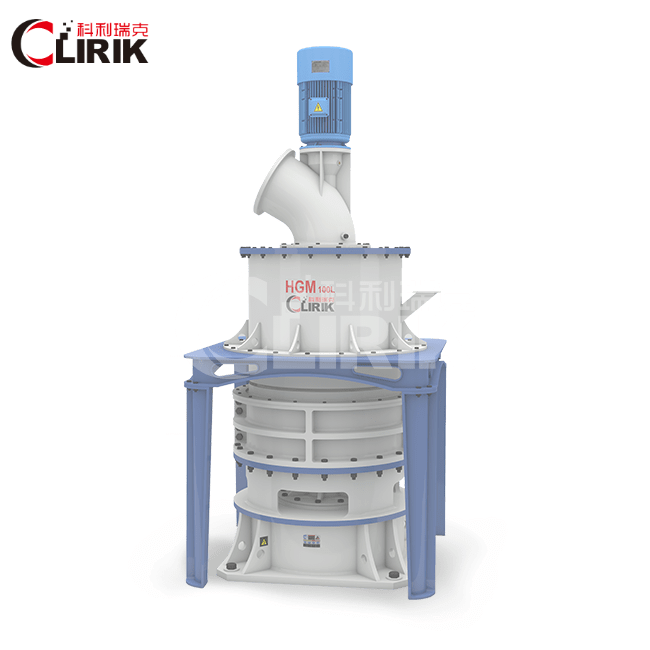

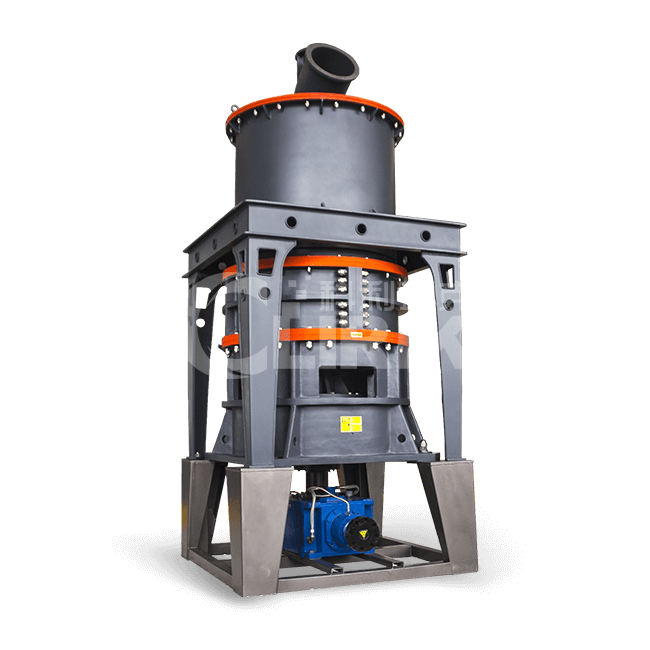

Other Products offered

If no roll crusher can not meet your needs, we have other mine grinding equipment for you to choose.

FAQ

Q: Are you a middle man or manufacturer?

A: Our Shanghai Clirik Machinery is a professional mining equipment manufacturer.

Q: What payment methods do you support?

A: T/T, L/C, D/P, D/A, Western Union, MoneyGram, Cash

Q: Where is your company?

A: We are in PuDong new area, HeQing twon, FuQing road, No. 19, Shanghai, China.

High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40