Table of Contents

Product overview of bamboo powder grinding mill

Bamboo powder ultrafine grinding mill can process 150-3000 mesh limestone powder, and the fineness can be adjusted freely.

The equipment has stable operation and good performance. The produced bamboo powder has good quality, high fine powder content, and a wide range of applications.

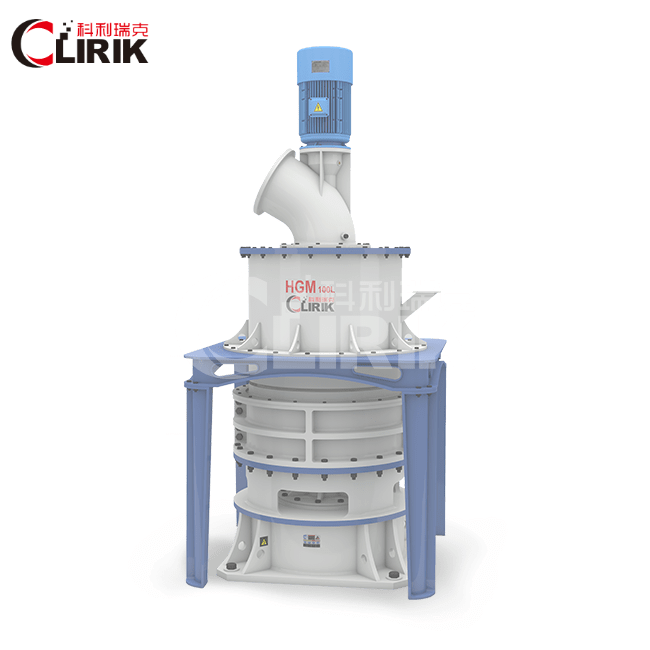

Bamboo Powder Ultrafine Grinding Mill

Adjustable fineness: 150-3000 meshes

Output: 0.5-45 t/h

Max feeding size: 10-25 mm

Applicable materials: Non-metallic ores, with Mohs hardness less than 6.

Such as bamboo, coconut shells, shells, cocoa shells, etc. It can also grind calcite, dolomite, calcium carbonate, barite, pumice, and other materials.

Features: The bamboo ultrafine grinding mill is a piece of energy-saving and consumption-reducing equipment for processing bamboo ultra-fine powder.

Small footprint, strong complete set, wide application, simple operation, convenient maintenance, stable performance, high-cost performance, it is an economical and practical ultrafine powder processing equipment.

Working principle of bamboo powder ultrafine grinding mill

Bamboo powder ultrafine grinding mill mainly consists of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After being crushed by a hammer crusher, the bamboo becomes small and is sent to a storage hopper by elevator.

And then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe.

When the bamboo powder grinding mill is at work, the main bearing and each dial are driven by the electromotor of the main equipment through a reducer.

And all the grinding rollers are rolling in the ring channels driving by dial through plunger.

The bamboo are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers.

And the bamboo powder is repeatedly pressed, crushed, and ground by the rollers in grinding chambers. Then the materials fall into multiple layers and to be crushed and ground continuously to micro powder.

Product featuers of bamboo powder ultrafine grinding mill

1. Meet client’s requirements for different fineness powder, finished powder fineness is adjustable and at stable quality.

2. Built-in high efficiency classifier, higher classification accuracy, better classification effect.

3. Use new upgraded main machine transmission mechanism, it has higher output, lower energy-consumption, easy maintenance.

4. All main wear parts use quality abrasion-resisting alloy steel, and have a longer working life.

5. The whole system works under negative pressure without dust emission, no coarse particle air pollution, more environment-friendly, higher fineness powder recovery.

6. Smart PLC controlled, remote centralized control, one-button easy operation, intelligent control of feeding material, all the above ensure grinding mill operation stable and high output.

7. The whole grinding mill system with a compact structure could save factory space, with a lower foundation construction cost, it’s a cost-effective investment. High quality Barite micro powder grinding mill for barite powder production line

By watching the video can be more intuitive understanding of bamboo powder ultrafine grinding mill.

Product parameter of bamboo powder ultrafine grinding mill

Parameter 1

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Parameter 2

| Unit kw | HGM80 | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Main unit | 75 | 2*45 | 132-150 | 132-150 | 185-200 | 315 |

| Classifier | 18.5 | 18.5-30 | 30-37 | 30-37 | 75 | 132 |

| Blower | 45 | 55 | 75 | 75 | 2*45-2*55 | 2*75-2*90 |

| Crusher | 18.5 | 18.5 | 18.5 | 18.5 | 45 | 75 |

| Bucket Elevator | 3 | 3 | 4 | 4 | 4 | 7.5 |

| Belt Conveyor Feeder | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2 |

| Discharging Valve | 2*0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 2*1.5 |

| Air Compressor | 11 | 15 | 22 | 22 | 37 | 55 |

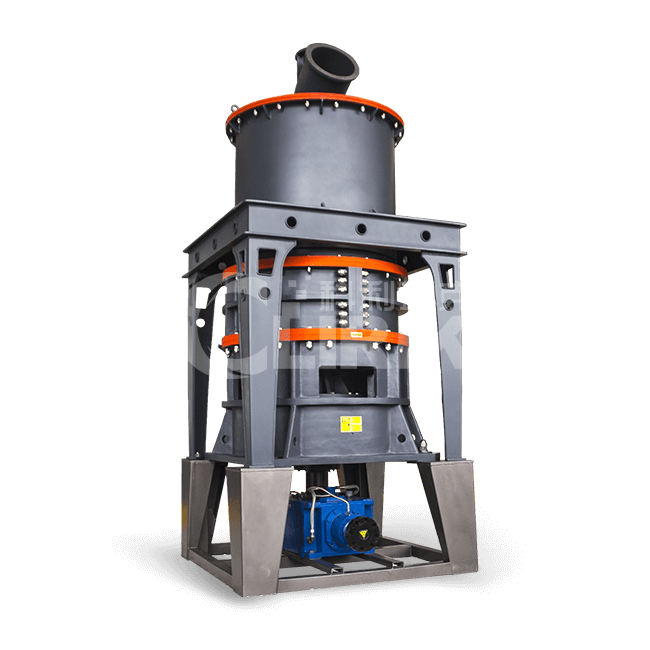

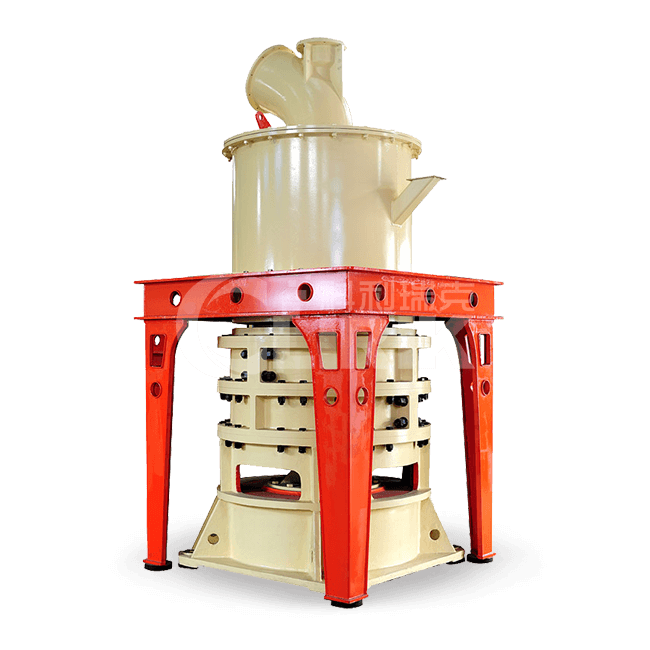

Other Products offered

In addition to HGM series bamboo powder ultrafine grinding mill, we have other bamboo mills for your choice.

What can we do for you?

When you purchase our bamboo powder ultrafine grinding mill we can provide you with the following services.

A.Pre-sale:

1.Equipment sizing assistance based on customer’s demand

2.Assistance in planning the layout of workshop according to customer’s site conditions

3.Assistance in designing and installation of the foundation drawing and process flow diagram based on customer’s demand.

4.Guidance on preparation work.

B. During sale:

1. Strict control of production to ensure product quality

2. Elimination of hidden dangers with strict factory inspection and traceability system.

3. Providing logistics information.

4. Guidance on the preparation of equipment foundation.

5. Guidance for installation and commissioning.

6. Offering professional technical training.

C. After-sale:

1. Guidance on various powder production processes for customers.

2. Periodic follow-up on device usage.

3. Instructions on equipment maintenance.

4. Solution of relevant problems in the shortest time.

5. Timely and efficient replacement of spare parts.

6. Professional and fast equipment maintenance.

Welcome to our company to visit, we will arrange all your schedule for you.

Related Products

Messages

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40