The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

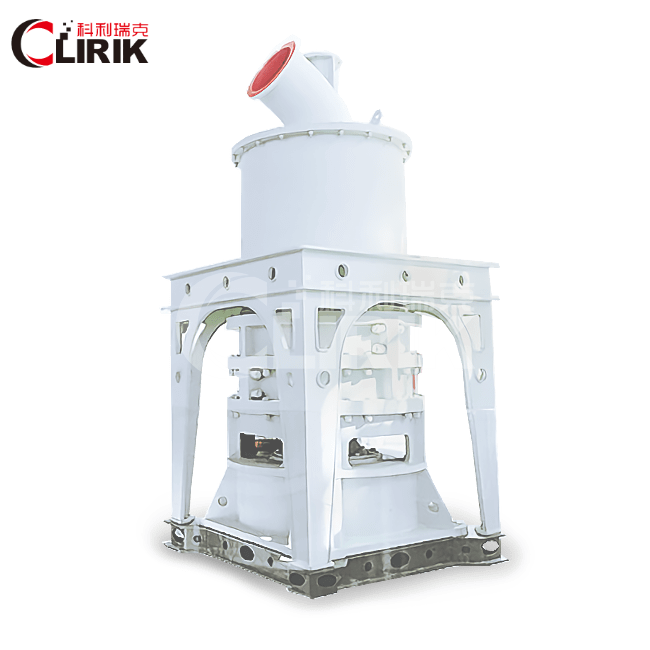

How to maintain a barite ultrafine powder grinding mill?

How to maintain a barite ultrafine powder grinding mill?

Maintaining a barite ultrafine powder grinding mill is crucial to ensure its efficiency and longevity. Here are some general maintenance tips that can help you keep your grinding mill in good working condition:

Regular Lubrication

The barite ultrafine powder grinding mill’s bearing and gears should be lubricated regularly to reduce friction and wear. Check the lubrication system regularly and ensure that the oil level is adequate.

Inspection

Regularly inspect the barite ultrafine powder grinding mill’s internal parts for any signs of wear and damage. Check the grinding rollers, grinding rings, and other parts for any signs of wear, cracks, or other damage. Replace any damaged or worn parts immediately.

Cleaning

Regularly clean the barite powder grinding mill’s internal parts, including the grinding chamber, grinding rollers, and grinding rings. Use a soft cloth or brush to remove any dirt or debris that may have accumulated.

Adjustments

Regularly check and adjust the ultrafine barite powder grinding mill’s settings, including the clearance between the grinding rollers and the grinding rings, to ensure optimal performance.

Maintenance Schedule

Create a maintenance schedule that includes regular inspections, cleaning, lubrication, and adjustments. Stick to the schedule to ensure that your barite ultrafine powder grinding mill is always in good working condition.

By following these tips, you can help ensure that your barite ultrafine powder grinding mill runs smoothly and efficiently for many years to come.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40