The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

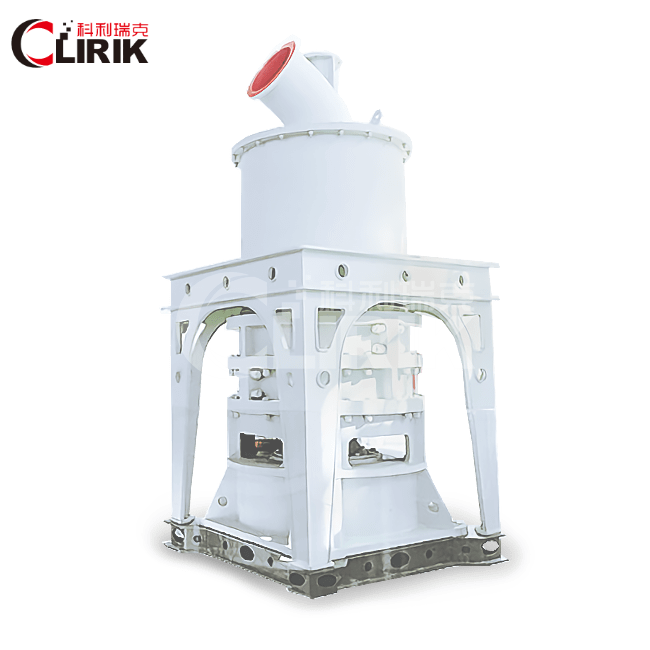

What are the safe operation precautions of GLG series powder modification machine?

What are the safe operation precautions of GLG series powder modification machine?

The operator of the GLG series powder modification machine must be trained in safe operation. The operator without training is not allowed to operate the powder modification machine alone. The following safety procedures need to be followed when operating the modifier.

- Check the machine before use.

(1) Before starting the machine, it should be checked whether the belt of the modifier is loose, damaged or fallen off, whether there are any foreign bodies in the modifier (if there are any, it should be cleaned up) and whether the rotation is sensitive.

(2) Check whether the oil is normal.

(3) Check whether the inlet valve and inlet valve switch are sensitive.

(4) Check whether the power supply, air source and motor are normal.

(5) When the above items are confirmed to be normal, the machine can be started.

- Start the device normally.

(1) Turn on the pulse back blowing of the bag filter.

(2) Check and ensure that the material inlet valve and air inlet valve are closed.

(3) Start the fan, wait for the fan to start, the current increases from small, then decreases from the highest point, and stabilizes for about 10 seconds, then the subsequent operation can be carried out.

(4) Open the air inlet valve and adjust the air volume.

(5) Start the motor once. For each motor, the second one can be started only after the current is stable for 10 seconds.

(6) Open the feed valve and adjust the speed of the screw feed converter

(7) Open the star blanking valve.

(8) Start the automatic packing machine.

- Stop the machine normally.

When the production task has been completed, or other reasons need to stop the machine, according to the following method:

(1)Close the feed material screw and feed material valve and stop feeding.

(2) After all the materials in the modified machine are removed, turn off the motor successively (waiting time is about 30 seconds).

(3)Close the fan and inlet valve.

(4) Close the star blanking valve.

(5) Turn off the automatic packing machine.

(6) Turn off the pulse back blowing of the bag filter.

- Stop the machine for inspection.

(1) Check whether the power supply and air source of the device are turned off.

(2) Check and clean the residual materials in the machine.

(3) Clean the production site around the machine and remove dust and debris from the equipment.

(4) Put the remaining raw materials in order.

(5) Clean up the packaging bags and items unrelated to production and put them in the prescribed position.

(6) Do well in equipment hygiene and on-site hygiene.

Matters needing attention:

1.The system must be started in strict accordance with the operating sequence.

2.Pay attention to the sound of the machine at any time in the production process, and observe the change of motor current. If the sound increases and the current exceeds the specified value, the feed quantity should be reduced as soon as possible to avoid the accident of machine stuck or motor burned.

3.It is necessary to judge whether the pipeline is blocked according to the output of the machine. When the output becomes significantly smaller, it is necessary to beat the bin and pipeline with a plastic hammer to dredge the system and ensure normal production.

For more information, you can click here.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40