The primary use of barite powder is as a weighting agent in drilling fluids used in oil and gas exploration and production.

China high quality Barites micro grinding mill equipment for barites powder process

China high quality Barites micro grinding mill equipment for barites powder process

Table of Contents

Barite powder introduction

Micro barite powder ( barium sulphate power), its crystal particle size average (D50) 0.8-1um in diameter, and (D96) 2um, has the best spacing capability to TiO2 powder.

Micro crystal particle has the most ideal surface energy, and the most stable combination with other organic and inorganic dye particles.

It to highly spread and supported TiO2 particles and other dye particles can promote theological property and dispersion stability of the painting material, and prevent the invasion of big particles, so totally ensure the entire function of products.

Micro barite powder ( barium sulphate power) has high BaSO4 content as to 98% win, has an excellent chemical stability and durability, it’s high whiteness of 95% win, makes the products have a very good hiding rate, to ensure the pure colour of products, which can be adjusted.

Using our high quality Barites micro grinding mill equipment, your products will have high brightness, rub-durable, anti-collision, high strength durable, absorb radiation.

Barite powder Application

Barite powder, in white or grey color, is an important mineral containing barium.It has many advantages, such as strong chemical inet, good stability, acid and alkali proof, high density, moderate rigidity, high whiteness, absorb in harmful rays (X ray and Y ray), no poison and no magnetism.

Barite is widely used in the fields of chemistry, paint, rubber, glass, paper, pottery and medicine etc.According to the latest statistics, barite powder has more than 2000 kinds of uses.

1. When used in dope and paint, barite powder can be used as the filler and can take the place of some expensive materials such as barium sulphated precipitated, titanium dioxide etc. in the manufacture of paint, it can control the viscosity of the paint compatibly to make the products with bright color and luster, good stability.

2. When used in the plastic industry, barite powder can be used as the filler of plastic ABS or make the products with bright color and luster.It can also improve the intensity, stiffness and abrasive resistance.

3. When used in the rubber industry, the product less than 28um can be used as the filler of rubber products. It can reduce cost and improve intensity and it is also acid, alkali and water proof.

4. When used in medicine, it can be used as barium, meal material for the intestines and stomach reflection, as the filler for plaster to increase the shelf life of the medicine.

5. When used in the paper making industry, barite powder with high fineness can be used as the filler to white paperboard and coat paper, thus improving the whiteness and percentage of coverage.

6. When used in cosmetics, barite powder looks white and gentle, harmless to skin, it can take the place of titanium dioxide.

7. Barite powder can also be used in the manufacturer of pottery.

Barite powder processing machine

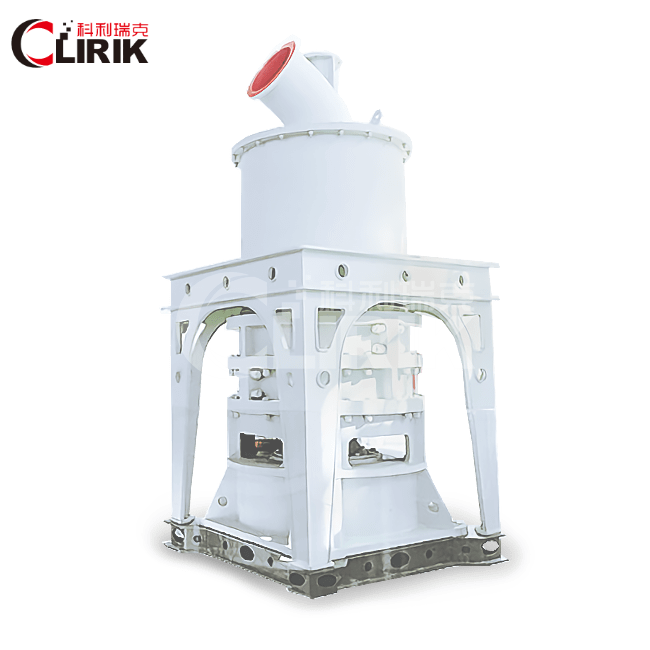

Barites micro grinding mill equipment

Barites micro grinding mill equipment is the suitable machine to be used in Barite mining industry. As a professional mining mill equipments manufacturer in China, we can supply perfect Barite processing solution for grinding barite.

According to customer’s specific requirements, we can choose Barite Raymond mill (Raymond roller Barite mill), high pressure suspension grinding mill, Barite micro powder grinding mill equipments in the grinding production line.

The Barites micro grinding mill equipment is for super-fine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite , gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 325-2500 meshes (0.044-0.0055mm).

Barite Powder Processing procedure

Barite ore from the mine to the mill where it is crushed. Firstly, the Barite will be primary crushed by jaw crusher. Then the coarse Barite will be entered the barites micro grinding mill equipment for power processing by the belt conveyor.

Barite mine raw ores → Barite crushing → screening → Barites micro grinding mill equipment → Packing

Barites micro grinding mill equipment parameter

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

You can choose the model you need according to your needs. If you would like more information please click here to leave us a message or ask our customer service directly and our sales manager will contact you later.

Scan the QR code to read on your phone

Contact Us

No.19, Fuqing Rd, Pudong New Area, Shanghai, China

Phone: Manager Li +86 13512137665

Copyright © 2015 Clirik All Rights Reserved. Lu ICP 09056488-40